Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

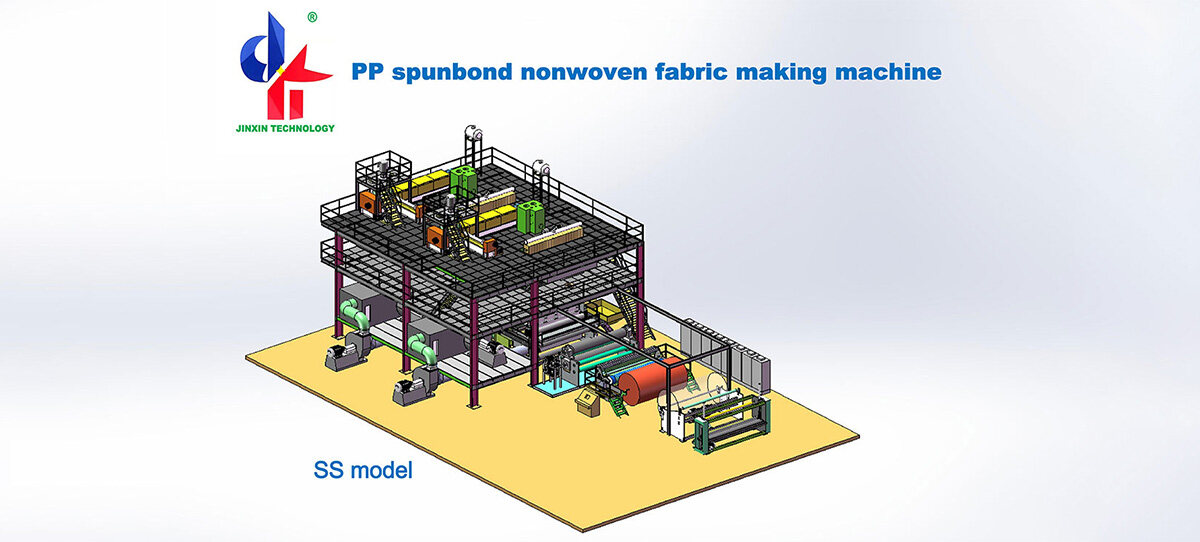

Ligne de production de machines non tissées SS

If the spunbond nonwoven production line is not regularly maintained, the equipment's parts and components could become worn out and the spunbond nonwoven machine could break down. The machine that produces spunbond nonwoven fabric has the unique maintenance procedures listed below.

| Model | JX-SS | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 30*12*12m | 30*14*12m | 30*16*12m |

| Mechanical Speed | 300m/min | 300m/min | 300m/min |

| Gram Weight | 10-200g/m2 | 10-200g/m2 | 10-200g/m2 |

| Daily Output | 7-12T/Day | 12-15T/Day | 14-20T/Day |

| Transformer Capacity | ≈400KVA | ≈500KVA | ≈600KVA |

| Power Consumption | 520°-650°Ton | 520°-650°Ton | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

How To Maintain The Spunbond Nonwoven Production Line?

If the spunbond nonwoven production line is not maintained frequently, the components and parts of the equipment may be worn out, and the spunbonded nonwoven machine may malfunction. The following is the specific maintenance method of the spunbond nonwoven fabric machine.

Routine maintenance

First of all, the main maintenance content of the spunbond nonwoven fabric production line is cleaning, tightening, adjustment, lubrication, and corrosion protection.

Secondly, the mechanical department of each project needs to strictly perform various maintenance tasks according to the specified cycle according to the maintenance manual and maintenance procedures of the mechanical equipment, reduce the wear rate of the parts, eliminate the hidden danger of failure, and extend the service life of the machinery.

Routine maintenance is required, focusing on cleaning, lubrication, inspection, and tightening. Routine maintenance is performed independently by the mechanical operator, and proper maintenance is required regularly.

Regular maintenance

1.The first-level maintenance work is carried out based on routine maintenance. The key word content is lubrication, tightening, and inspection of all relevant parts and cleaning.

2.The secondary maintenance work focuses on inspection and adjustment. Specifically, check the working conditions of the motor, transmission, transmission mechanism, working device, pneumatic system, and electrical system, and make necessary adjustments to eliminate the faults found. Ensure that the mechanical components and parts have good working performance.

3.The focus is to detect, adjust, eliminate hidden troubles and balance the degree of wear and tear of various parts. Diagnose and check the parts that affect the performance and the parts with fault signs, and then complete the necessary replacement, adjustment, and troubleshooting.

Spunbond nonwoven fabric production line is relatively large-scale equipment, we need to pay attention to many problems in cleaning and maintenance. If you want to know more about the maintenance of spunbond nonwoven fabrics machine after reading the above methods, you can contact us for more information and solutions.

As a manufacturer specializing in the production of nonwoven machines, we have a professional design team and a complete production team that can provide you with high-quality products. Our professional after-sales service team can provide you with thoughtful one-stop service and comprehensive solutions. If you want to buy our high-quality spunbond nonwoven machine, please contact us immediately!